Why Shinnoki® Cabinets?

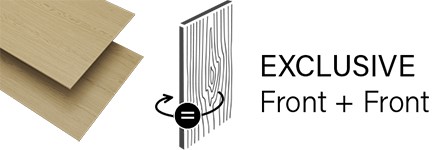

It's not hard to fall in love with custom cabinets with Shinnoki door collection, and below are six major reasons. Made of Real Wood VeneerThe top and bottom layers of Shinnoki doors are sheets of wood veneer, brushed, stained and lacquered to perfection to preserve the timeless elegance of real oak, walnut and eucalyptus wood. Our custom cabinetry use only the Exclusive grade Shinnoki panels, in which both front and back of the panel are with the least color and grain pattern variation.

Wide-Ranging Color ChoicesFrom pure naturals to luxuriant black, our custom Shinnoki door collection offers a wide range of color and pattern choices that effortlessly fit any palette or style. Paired with modern kitchen appliances, a Shinnoki custom kitchen feels contemporary and timeless all at once. Patented Mix & Match TechniqueMastered over decades, Decospan's patented technique guarantees a uniform surface for every Shinnoki sheet. Various slicing techniques are applied to select cuts of timber from different trees, then jointed together onto a sheet. Each Shinnoki door or panel is characteristically unique, without visual inconsistencies or structural compromises.

Made for Daily Wear & TearAlthough made of real wood veneers, Shinnoki doors and panels are finished with a six-layer state-of-the-art varnishing process that provides the ultimate protection against water, liquids and scratches. Furthermore, we use matching 1mm thick ABS edge banding for our Shinnoki custom cabinets, and they are as convenient and sturdy as any other in the market, and perfect for daily use in a modern kitchen. In most cases, a soft dry cloth is all you need to clean your Shinnoki doors. Bendability for Floating ShelvesThe Shinnoki top veneer layer is a bendable sheet made up of stained and lacquered real wood veneers laminated to a paper impregnated with a phenolic resin. As a result, they are bendable to create stunning zero-edge floating shelves.

Watch a video that illustrates the fabrication process of creating a zero edge:

SustainabilityAs a leading manufacturer of veneer-based products, Shinnoki’s manufacturer Decospan has made the efficient and responsible usage of natural wood material as its unconditional basic principle. Green energy, including solar and wind, has been used extensively during Shinnoki panels’ manufacturing process. Its proprietary mix & match technique ensures maximum yield and efficiency for the wood veneers. Furthermore, the core material MDF is CARB 2 compliant. Both wood veneer and MDF materials are sourced from responsible forestry and are FSC certified. |

Domain Cabinets

Domain Cabinets

42225 Remington Ave. #A11

92590

Temecula, CA,

888-872-2246,